Introduction

Mini excavators have revolutionized the utility installation industry, providing the perfect balance of power, precision, and maneuverability for digging narrow, controlled trenches. These compact machines, typically weighing between 1 to 8 tons, have become the go-to equipment for installing essential underground services including water pipes, electrical lines, gas mains, and fiber-optic cables. Their ability to work in confined spaces while maintaining surgical precision makes them indispensable for modern infrastructure projects.

Key Applications in Utility Installation

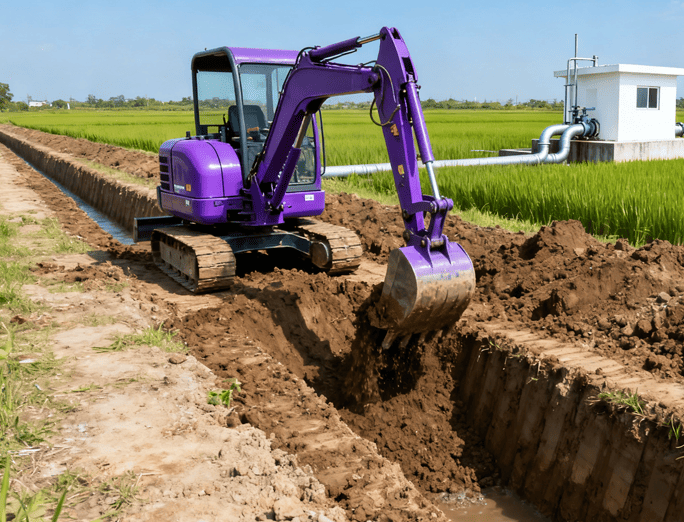

Water Pipe Installation

Mini excavators excel at creating the precise trenches required for water distribution systems. Their hydraulic controls allow operators to dig to exact depths, ensuring pipes are buried below the frost line in cold climates. The machines can create trenches with clean, vertical walls, reducing the amount of backfill needed and providing proper support for the pipes. The zero-tail-swing design enables work in tight residential areas without damaging existing landscaping or structures.

Electrical Conduit Placement

For underground electrical installations, mini excavators provide the precision needed to meet strict code requirements. They can dig trenches with specific separation distances from other utilities, preventing interference and ensuring safety. The ability to work around existing infrastructure makes them ideal for urban upgrades and new construction projects where space is limited.

Gas Main Installation

Natural gas distribution requires meticulous trenching to ensure safety and reliability. Mini excavators offer the control needed to install gas pipes at precise depths with proper bedding materials. Their compact size allows them to navigate through residential neighborhoods and commercial areas with minimal disruption to daily activities.

Fiber-Optic Cable Installation

The delicate nature of fiber-optic cables demands careful handling during installation. Mini excavators can create narrow trenches (as narrow as 6 inches) that protect the cables from damage while maintaining the required bend radius. Their precision controls allow operators to work around existing utilities without causing service interruptions.

Advantages of Mini Excavators in Utility Trenching

Precision and Control

The hydraulic systems of modern mini excavators provide millimeter-level precision, allowing operators to create trenches with exact dimensions. This precision reduces material waste, minimizes backfill requirements, and ensures utilities are installed at the correct depth and alignment.

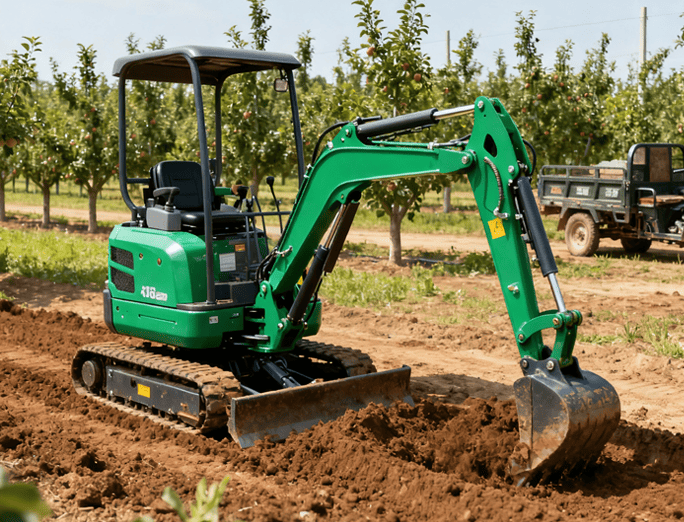

Maneuverability in Confined Spaces

Unlike larger equipment, mini excavators can access backyards through standard gates, work in narrow alleys, and operate around existing structures. Their compact size and zero-tail-swing design make them ideal for urban environments where space is at a premium.

Reduced Site Disturbance

Mini excavators cause minimal disruption to the surrounding area. Their low ground pressure (typically 3-5 psi) means they can work on finished surfaces without causing damage to lawns, driveways, or sidewalks. This is particularly important in residential areas where preserving landscaping is a priority.

Versatility with Attachments

The ability to quickly change attachments makes mini excavators incredibly versatile. For utility trenching, operators can switch between narrow buckets for precise digging, hydraulic thumbs for handling pipes and materials, and augers for post-hole digging. This versatility allows a single machine to handle multiple tasks on a project site.

Cost Efficiency

Mini excavators offer excellent value for utility contractors. They consume less fuel than larger equipment (typically 1-2 gallons per hour), have lower transportation costs, and can be operated by a single person. Their efficiency in completing projects quickly translates to reduced labor costs and faster project turnaround times.

Specialized Features for Utility Work

Narrow Buckets

Mini excavators can be equipped with buckets as narrow as 6 inches, perfect for creating the precise trenches needed for utility lines. These narrow buckets minimize soil disturbance and reduce the amount of material that needs to be removed and replaced.

Hydraulic Thumbs

The hydraulic thumb attachment transforms the mini excavator into a material handling machine. It can grip and position pipes, conduits, and other materials with precision, reducing the need for manual labor and improving safety on the job site.

Grade Control Systems

Many modern mini excavators are equipped with grade control technology that helps operators maintain consistent depth and slope throughout the trench. This technology reduces the need for constant measurement and ensures utilities are installed to exact specifications.

Quick Coupler Systems

Quick couplers allow operators to change attachments in minutes, increasing productivity and reducing downtime. This is particularly valuable on utility projects where different tasks require different tools throughout the day.

Safety Considerations

Utility Location

Before beginning any trenching operation, it's essential to locate and mark existing underground utilities. Mini excavators, despite their precision, can still cause damage if operators are unaware of what lies beneath the surface.

Trench Safety

Even with narrow trenches, proper shoring or trench boxes may be required depending on soil conditions and depth. Mini excavators can be used to install protective systems, but operators must follow all safety regulations regarding trench work.

Operator Training

Proper training is essential for safe and efficient operation. Operators should be certified and familiar with the specific machine they're using, as well as the safety protocols for utility installation work.

Environmental Benefits

Reduced Soil Compaction

The low ground pressure of mini excavators means they cause significantly less soil compaction than larger equipment or even repeated foot traffic. This helps preserve soil structure and promotes healthy root growth in surrounding vegetation.

Minimal Surface Disruption

Because mini excavators can work in tight spaces and create narrow trenches, they minimize the amount of surface area that needs to be disturbed. This reduces erosion, preserves existing landscaping, and speeds up site restoration after the project is complete.

Efficient Material Management

The precision of mini excavators allows for targeted excavation, meaning less material needs to be removed from the site. This reduces transportation requirements and the associated environmental impact.

Future Trends

Electric and Hybrid Models

The utility industry is increasingly adopting electric and hybrid mini excavators. These models offer zero emissions, reduced noise levels, and lower operating costs, making them ideal for work in residential areas and environmentally sensitive locations.

Advanced Technology Integration

GPS guidance systems, automated grade control, and telematics are becoming standard features on many mini excavators. These technologies improve accuracy, reduce operator fatigue, and provide real-time data on machine performance and project progress.

Enhanced Attachments

Manufacturers continue to develop new attachments specifically designed for utility work, including specialized buckets for different soil conditions, improved quick coupler systems, and attachments that can handle multiple functions.

Conclusion

Mini excavators have transformed the utility installation industry by providing the perfect combination of power, precision, and versatility. Their ability to dig narrow, precise trenches in confined spaces makes them essential for installing water pipes, electrical lines, gas mains, and fiber-optic cables. With their low environmental impact, cost efficiency, and ever-improving technology, mini excavators will continue to be the preferred choice for utility contractors looking to deliver high-quality installations with minimal disruption to the surrounding area. As urban areas become more densely populated and the demand for underground utilities continues to grow, the role of the mini excavator in building and maintaining our essential infrastructure will only become more important.