Introduction

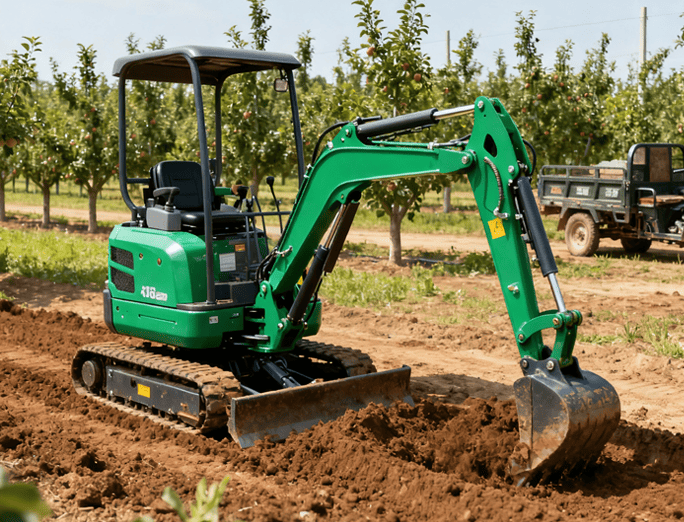

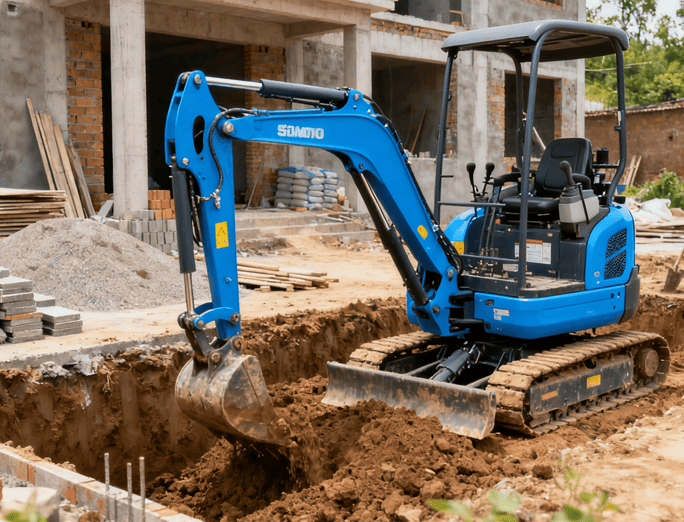

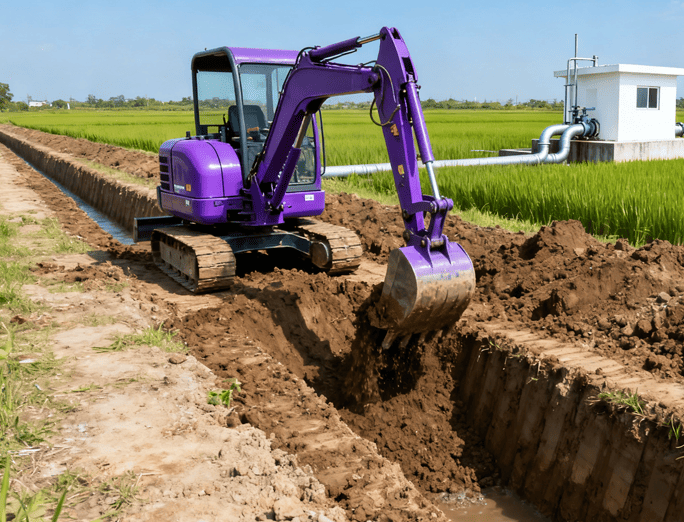

Mini excavators have revolutionized the process of stump and tree removal, offering a perfect combination of power, precision, and versatility for landscaping and land-clearing projects. These compact machines, typically weighing between 1 to 8 tons, are specifically designed to navigate residential properties, commercial sites, and challenging terrain while delivering the digging force needed to remove stubborn stumps and roots. Their ability to work in confined spaces and around existing structures makes them ideal for both large-scale land clearing and targeted tree removal in established landscapes.

Key Applications in Stump and Tree Removal

Stump Grinding and Removal

Mini excavators equipped with specialized stump grinder attachments can efficiently remove tree stumps of various sizes. The hydraulic power of these machines allows them to grind stumps down to below ground level, eliminating the need for manual digging and reducing the risk of regrowth. The precision control enables operators to work close to buildings, fences, and other structures without causing damage, making them perfect for residential properties where space is limited.

Root System Extraction

One of the most challenging aspects of tree removal is extracting the extensive root system. Mini excavators can dig around the stump, exposing the main roots and using their hydraulic power to break them free from the soil. The ability to work at different angles and depths allows for complete root removal, preventing future issues with regrowth or interference with underground utilities.

Small Tree Removal

For trees up to medium size, mini excavators can handle the entire removal process. They can dig around the base to expose roots, use the bucket or specialized attachments to push or pull the tree, and then process the stump and roots. This all-in-one capability makes them ideal for landscaping projects where multiple trees need to be removed.

Land Clearing and Site Preparation

Mini excavators are perfect for clearing small to medium-sized areas of trees and vegetation for new construction, agricultural expansion, or landscaping projects. They can work in tight spaces, navigate around existing trees that need to be preserved, and clear brush and debris efficiently.

Root Ball Excavation

For transplanting trees, mini excavators can carefully excavate around the root ball, preserving as much of the root system as possible. The precision control allows for minimal damage to the roots, increasing the tree's chances of survival after transplantation.

Advantages in Stump and Tree Removal

Precision and Control

The hydraulic controls of modern mini excavators provide surgical precision that is essential for stump removal near structures, utilities, and existing landscaping. Operators can make micro-adjustments to avoid damaging surrounding features while still applying significant digging force.

Access to Confined Spaces

The compact size and zero-tail-swing design allow mini excavators to work in backyards, between buildings, and in other tight spaces where larger equipment cannot access. This capability is crucial for residential projects where space is limited.

Versatility with Attachments

The ability to quickly change between buckets, stump grinders, hydraulic thumbs, and other attachments makes mini excavators incredibly versatile. A single machine can handle digging, grinding, material handling, and site cleanup.

Reduced Site Impact

Mini excavators have low ground pressure (typically 3-5 psi), which means they can work on lawns and finished surfaces without causing excessive damage. This reduces the amount of site restoration needed after the project is complete.

Efficiency and Cost-Effectiveness

Mini excavators can complete stump and tree removal projects faster than manual methods, reducing labor costs and project timelines. Their fuel efficiency and lower operating costs make them more economical than larger equipment for most residential and small commercial projects.

Specialized Features for Tree Removal

Zero-Tail-Swing Design

Most modern mini excavators feature zero-tail-swing or reduced-tail-swing designs, allowing them to rotate 360 degrees without the counterweight extending beyond the tracks. This feature is essential for working in tight spaces near buildings, fences, and property lines.

Hydraulic Thumbs

The hydraulic thumb attachment transforms the mini excavator into a material handling machine. It can grip and position stumps, logs, and other debris with precision, reducing the need for manual labor and improving safety.

Stump Grinder Attachments

Specialized stump grinder attachments can be mounted on mini excavators, allowing them to grind stumps down to below ground level. These attachments come in various sizes to handle different stump diameters.

Quick Coupler Systems

Quick couplers allow operators to change attachments in minutes, increasing productivity and reducing downtime. This is particularly valuable for tree removal projects where different tasks require different tools.

Enclosed Cabs

For year-round operation, enclosed cabs with heating and air conditioning provide operator comfort in all weather conditions, improving productivity and safety.

Safety Considerations

Utility Location

Before beginning any excavation for stump removal, it's essential to locate and mark existing underground utilities. Even with precision equipment, accidental contact with buried lines can be dangerous and costly.

Overhead Hazards

When removing trees, be aware of overhead power lines, branches, and other hazards. Maintain safe distances and use spotters when necessary.

Trench Safety

When digging around stumps and roots, ensure proper shoring or trench boxes are used for excavations deeper than 4 feet, depending on soil conditions.

Falling Debris

Use proper personal protective equipment and maintain safe distances from the work area to protect against falling branches and debris.

Operator Training

Proper training is essential for safe operation, including understanding the machine's capabilities, limitations, and the specific hazards associated with tree removal.

Environmental Benefits

Selective Removal

Mini excavators allow for targeted tree and stump removal, preserving surrounding vegetation and minimizing disturbance to the ecosystem.

Reduced Soil Compaction

The low ground pressure of mini excavators means they cause significantly less soil compaction than larger equipment or even repeated foot traffic. This helps preserve soil structure and promotes healthy root growth in surrounding vegetation.

Efficient Debris Management

The ability to process and handle debris on-site reduces the need for multiple pieces of equipment and minimizes the environmental impact of transportation.

Site Preservation

The precision of mini excavators allows for minimal disturbance to the surrounding area, preserving topsoil, existing landscaping, and natural features.

Future Trends

Electric and Hybrid Models

The landscaping industry is increasingly adopting electric and hybrid mini excavators for tree removal work. These models offer zero emissions, reduced noise levels, and lower operating costs, making them ideal for work in residential areas and environmentally sensitive locations.

Advanced Technology Integration

GPS guidance systems, 3D scanning, and augmented reality are being integrated into tree removal equipment to improve accuracy and efficiency. These technologies allow operators to visualize the work area and plan the removal process more precisely.

Enhanced Attachments

Manufacturers continue to develop new attachments specifically designed for tree removal, including more efficient stump grinders, multi-processor attachments, and tools with improved dust suppression capabilities.

Remote Operation

Remote-controlled mini excavators are becoming more common, allowing operators to control the machine from a safe distance. This technology is particularly valuable for hazardous tree removal work or work in confined spaces.

Conclusion

Mini excavators have transformed the stump and tree removal industry by providing the perfect combination of power, precision, and versatility for landscaping and land-clearing projects. Their ability to work in confined spaces while delivering the performance needed for complete stump and root removal makes them essential for both residential and commercial applications. With their low environmental impact, improved safety features, and ever-advancing technology, mini excavators will continue to be the preferred choice for contractors and landscapers looking to perform efficient, precise, and sustainable tree removal work. As urban areas become more densely populated and the demand for landscaping services grows, the role of the mini excavator in maintaining and transforming outdoor spaces will only become more important.