Introduction

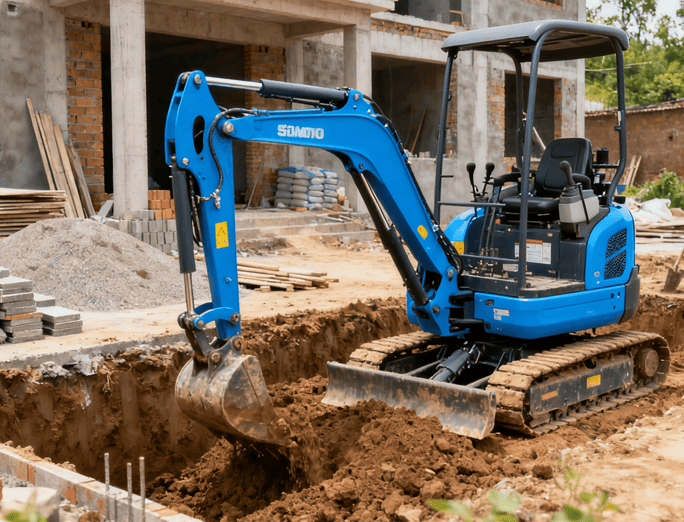

Mini excavators have emerged as game-changers in the demolition industry, particularly for indoor and controlled demolition projects where precision and maneuverability are paramount. These compact machines, typically weighing between 1 to 8 tons, are specifically engineered to navigate through standard doorways, work in tight interior spaces, and perform selective demolition with surgical precision. Their ability to operate in confined environments while delivering controlled power makes them indispensable for interior renovations, historic preservation, and complex demolition projects where traditional equipment would be impractical or impossible to use.

Key Applications in Controlled Demolition

Selective Interior Demolition

Mini excavators excel at targeted demolition work inside buildings, allowing contractors to remove specific walls, floors, or structural elements while preserving surrounding structures. Their hydraulic controls enable operators to work with millimeter-level precision, making them ideal for projects that require careful removal of materials without damaging adjacent finishes or structural components. This capability is particularly valuable in renovation projects where only portions of a building need to be removed or modified.

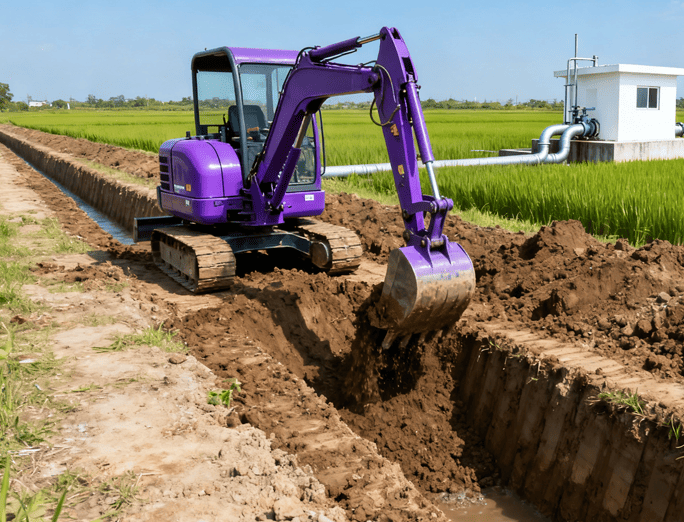

Wall and Partition Removal

The compact size and zero-tail-swing design of mini excavators make them perfect for removing interior walls and partitions. They can work in narrow hallways and small rooms, using specialized attachments like hydraulic breakers and concrete crushers to dismantle walls efficiently. The ability to control the machine's movements precisely allows operators to work close to existing finishes, electrical systems, and plumbing without causing collateral damage.

Floor and Slab Demolition

Mini excavators equipped with hydraulic breakers or concrete pulverizers can effectively remove concrete floors, slabs, and foundations. Their low ground pressure and compact footprint allow them to work on upper floors of buildings (when properly supported) and in basements where access is limited. The machines can break concrete into manageable pieces and use hydraulic thumbs to load debris into containers or conveyors.

Debris Removal and Material Handling

The hydraulic thumb attachment transforms mini excavators into efficient material handling machines for debris removal. They can grip and move large pieces of concrete, wood, and other demolition materials, reducing the need for manual labor and improving safety on the job site. The ability to work in confined spaces means debris can be loaded directly into containers or chutes without the need for extensive material handling equipment.

Advantages in Indoor Demolition

Access to Confined Spaces

The compact dimensions of mini excavators allow them to access buildings through standard doorways (as narrow as 3 feet), work in small rooms, and navigate through narrow hallways. This capability is crucial for interior demolition projects where space is limited and traditional equipment cannot be used.

Precision and Control

The hydraulic systems of modern mini excavators provide exceptional control, allowing operators to perform delicate demolition work with surgical precision. This is essential for projects that require selective removal of materials while preserving adjacent structures, finishes, or historical elements.

Reduced Structural Impact

Mini excavators have low ground pressure (typically 3-5 psi), which means they can work on finished floors and structural slabs without causing damage. This is particularly important in renovation projects where the existing structure must remain intact.

Versatility with Attachments

The ability to quickly change attachments makes mini excavators incredibly versatile for demolition work. Operators can switch between hydraulic breakers for concrete demolition, concrete crushers for processing materials, hydraulic thumbs for material handling, and buckets for debris removal—all with a single machine.

Improved Safety

By performing demolition work from the operator's cab, mini excavators reduce the risk of injury to workers who would otherwise need to work in hazardous conditions. The enclosed cab provides protection from falling debris, dust, and other hazards associated with demolition work.

Specialized Features for Demolition Work

Zero-Tail-Swing Design

Most modern mini excavators feature zero-tail-swing or reduced-tail-swing designs, allowing them to rotate 360 degrees without the counterweight extending beyond the tracks. This feature is essential for working in tight interior spaces where every inch counts.

Hydraulic Breakers and Crushers

Specialized demolition attachments, including hydraulic breakers, concrete crushers, and pulverizers, can be easily mounted on mini excavators. These attachments allow the machines to break concrete, crush materials on-site, and process debris for recycling.

Hydraulic Thumbs

The hydraulic thumb attachment is essential for demolition work, allowing the machine to grip and manipulate large pieces of debris, concrete slabs, and other materials. This reduces the need for manual handling and improves efficiency.

Dust Suppression Systems

Many mini excavators used for indoor demolition are equipped with dust suppression systems, including water misting attachments and enclosed cabs with air filtration. These systems help control dust and improve air quality in confined spaces.

Low Noise and Vibration

Modern mini excavators are designed with features that reduce noise and vibration, making them suitable for work in occupied buildings, hospitals, schools, and other sensitive environments.

Safety Considerations

Structural Assessment

Before beginning any indoor demolition work, a thorough structural assessment must be conducted to ensure the building can support the weight of the mini excavator and the forces generated during demolition.

Utility Disconnection

All utilities (electrical, gas, water, etc.) must be properly disconnected and marked before demolition begins. Even with precision equipment, accidental contact with live utilities can be dangerous.

Dust and Air Quality Control

Indoor demolition generates significant dust and airborne particles. Proper ventilation, dust suppression systems, and personal protective equipment are essential to protect workers and building occupants.

Fall Protection

When working on upper floors or near openings, proper fall protection measures must be in place to prevent the machine or operator from falling through the structure.

Operator Training

Operators must be properly trained and certified for demolition work, including understanding the specific hazards associated with indoor demolition and the capabilities of the equipment.

Environmental Benefits

Selective Demolition

Mini excavators enable selective demolition, which allows for the preservation of reusable materials and reduces the amount of waste sent to landfills. This approach is more sustainable than traditional "wrecking ball" demolition.

Material Recycling

The precision of mini excavators allows for the separation of materials on-site, making it easier to sort concrete, metal, wood, and other materials for recycling. This reduces the environmental impact of demolition projects.

Reduced Energy Consumption

Mini excavators consume less fuel than larger demolition equipment, and their ability to work efficiently in confined spaces reduces the need for additional equipment and transportation.

Minimal Site Disturbance

Because mini excavators can work precisely and in confined spaces, they minimize disruption to surrounding areas and reduce the amount of material that needs to be removed from the site.

Future Trends

Electric and Hybrid Models

The demolition industry is increasingly adopting electric and hybrid mini excavators for indoor work. These models offer zero emissions, reduced noise levels, and lower operating costs, making them ideal for work in occupied buildings and environmentally sensitive areas.

Advanced Technology Integration

GPS guidance systems, 3D scanning, and augmented reality are being integrated into demolition equipment to improve accuracy and efficiency. These technologies allow operators to visualize the structure being demolished and plan the work more precisely.

Enhanced Attachments

Manufacturers continue to develop new attachments specifically designed for demolition work, including more efficient hydraulic breakers, multi-processor attachments that can handle multiple tasks, and attachments with improved dust suppression capabilities.

Remote Operation

Remote-controlled mini excavators are becoming more common, allowing operators to control the machine from a safe distance. This technology is particularly valuable for hazardous demolition work or work in confined spaces with poor air quality.

Conclusion

Mini excavators have transformed the demolition industry by providing the perfect combination of power, precision, and versatility for indoor and controlled demolition projects. Their ability to work in confined spaces while delivering controlled demolition capabilities makes them essential for interior renovations, historic preservation, and complex demolition work. With their low environmental impact, improved safety features, and ever-advancing technology, mini excavators will continue to be the preferred choice for demolition contractors looking to perform precise, efficient, and sustainable demolition work in challenging environments. As urban areas become more densely populated and the demand for building renovations and adaptive reuse projects grows, the role of the mini excavator in the demolition industry will only become more important.