Introduction

Mini excavators have revolutionized material handling and loading operations across various industries, offering a perfect blend of power, precision, and versatility for modern job sites. These compact machines, typically weighing between 1 to 8 tons, are specifically designed to handle the demanding tasks of lifting, moving, and positioning heavy materials with efficiency and control. Their ability to work in confined spaces while delivering substantial lifting capacity makes them indispensable for construction, landscaping, agriculture, and industrial applications where traditional material handling equipment would be impractical or inefficient.

Key Applications in Material Handling

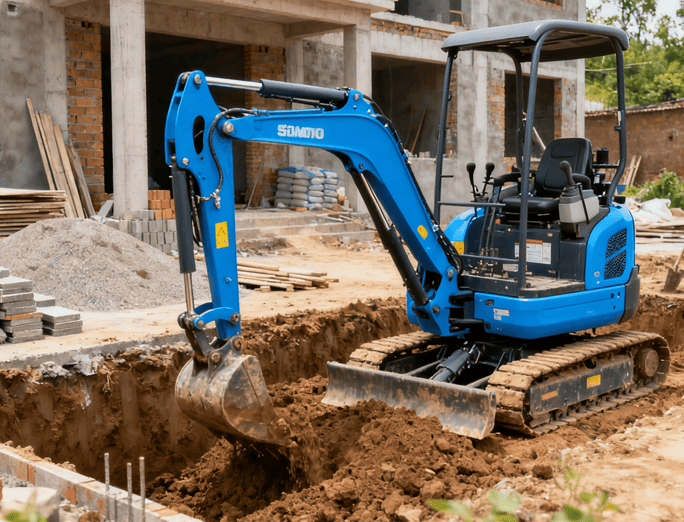

Construction Site Material Management

Mini excavators excel at moving construction materials such as lumber, steel beams, concrete blocks, and rebar around job sites. Their hydraulic power and precise control allow operators to position materials exactly where they're needed, reducing the need for manual labor and improving overall site efficiency. The ability to work in tight spaces between buildings, in basements, or on multi-story construction sites makes them particularly valuable for urban construction projects where space is limited.

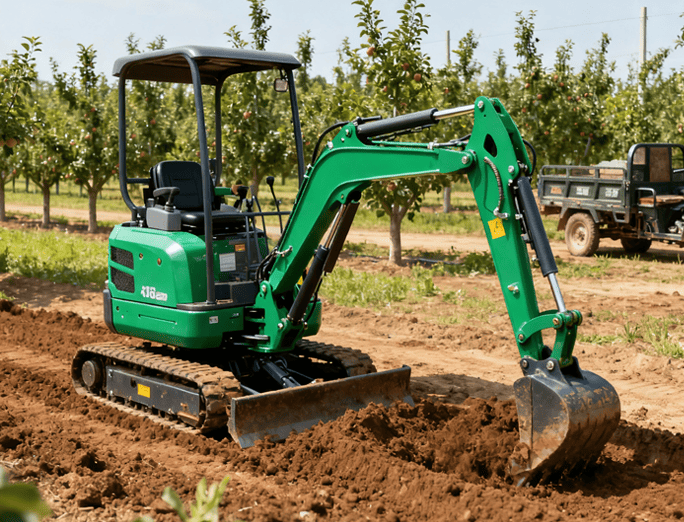

Landscaping and Hardscaping Material Handling

For landscaping projects, mini excavators can move and position heavy materials like boulders, pavers, retaining wall blocks, and large planters with precision. The hydraulic thumb attachment allows operators to grip and place materials exactly where they're needed, creating natural-looking rock formations, precise paver installations, and carefully positioned hardscape elements. This capability reduces the need for manual labor and minimizes the risk of damage to materials during handling.

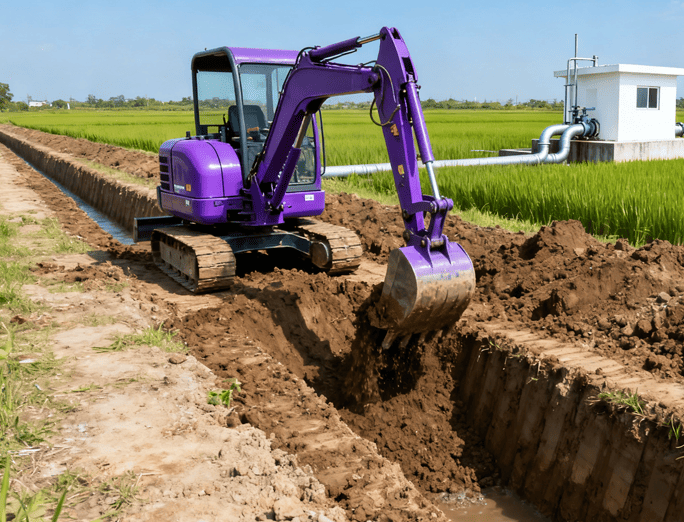

Agricultural Material Transport

On farms and agricultural operations, mini excavators are essential for moving feed, fertilizer, bedding materials, and harvested crops. They can load and unload trucks, move materials between storage areas, and distribute feed to livestock. The ability to work in confined spaces like barns and storage sheds allows for efficient material management without the need for multiple pieces of equipment.

Debris and Waste Management

Mini excavators are perfect for loading and moving construction debris, demolition waste, and other materials into dumpsters or trucks. The hydraulic thumb attachment allows them to grip and load irregularly shaped materials efficiently, reducing the need for manual sorting and handling. This capability is particularly valuable for cleanup operations after construction or demolition projects.

Loading and Unloading Operations

Mini excavators can serve as efficient loading machines for trucks, trailers, and other transport equipment. Their ability to reach over obstacles and position materials precisely makes them ideal for loading operations where space is limited or access is challenging. The quick attachment change systems allow them to switch between buckets for bulk materials and grapples for individual items.

Advantages in Material Handling

Precision and Control

The hydraulic controls of modern mini excavators provide exceptional precision, allowing operators to position materials with millimeter-level accuracy. This is essential for tasks like placing boulders in landscaping, positioning structural elements in construction, or loading delicate materials without damage.

Versatility with Quick Attachment Changes

The ability to quickly change between buckets, hydraulic thumbs, grapples, and other attachments makes mini excavators incredibly versatile. A single machine can handle multiple material handling tasks throughout the day, reducing the need for multiple pieces of equipment and lowering overall project costs.

Access to Confined Spaces

The compact size and zero-tail-swing design allow mini excavators to work in tight spaces where larger equipment cannot access. This capability is crucial for urban construction sites, interior demolition projects, and other applications where space is limited.

Reduced Ground Pressure

Mini excavators have low ground pressure (typically 3-5 psi), which means they can work on finished surfaces, lawns, and other sensitive areas without causing excessive damage. This reduces the need for site protection and restoration after material handling operations.

Cost Efficiency

Mini excavators offer excellent value for material handling operations. They consume less fuel than larger equipment, have lower maintenance costs, and can be operated by a single person, reducing labor expenses. Their versatility means they can replace multiple pieces of equipment, further reducing capital investment.

Specialized Features for Material Handling

Hydraulic Thumb Attachments

The hydraulic thumb is perhaps the most important attachment for material handling applications. It transforms the mini excavator into a versatile material handler, allowing it to grip and move individual items like boulders, logs, and construction materials with precision. The thumb can be adjusted to different positions to accommodate various material sizes and shapes.

Grapple Attachments

Specialized grapple attachments are designed for specific material handling tasks. Log grapples for forestry work, scrap grapples for demolition debris, and multi-purpose grapples for general material handling all provide enhanced gripping power and control for different applications.

Quick Coupler Systems

Quick couplers allow operators to change attachments in minutes, increasing productivity and reducing downtime. This is particularly valuable for material handling projects where different tasks require different tools throughout the day.

Tiltrotator Systems

Advanced tiltrotator attachments provide 360-degree rotation and tilt capabilities, allowing for more precise material positioning. This feature is essential for tasks that require exact placement, such as setting stones in landscaping or positioning structural elements in construction.

Enclosed Cabs

For year-round operation, enclosed cabs with heating and air conditioning provide operator comfort in all weather conditions, improving productivity and safety.

Safety Considerations

Load Capacity Awareness

Always be aware of the machine's rated load capacity and never exceed it. Overloading can cause the machine to become unstable and potentially tip over.

Proper Lifting Techniques

Use proper lifting techniques, keeping the load as close to the machine as possible and avoiding sudden movements. Always lift with the machine on level ground and with the tracks properly positioned for stability.

Overhead Hazards

Be aware of overhead power lines, structures, and other hazards when lifting and moving materials. Maintain safe distances and use spotters when necessary.

Pinch Points and Crush Hazards

Be aware of pinch points between the machine and materials, and between moving parts of attachments. Keep hands and other body parts clear of these areas during operation.

Operator Training

Proper training is essential for safe material handling operations, including understanding the machine's capabilities, limitations, and the specific hazards associated with different types of materials.

Environmental Benefits

Reduced Soil Compaction

The low ground pressure of mini excavators means they cause significantly less soil compaction than larger equipment or even repeated foot traffic. This helps preserve soil structure and promotes healthy plant growth in landscaping and agricultural applications.

Efficient Material Movement

The ability to handle materials precisely reduces the amount of material that needs to be moved multiple times, minimizing fuel consumption and reducing the environmental impact of the project.

Reduced Site Disturbance

The precision of mini excavators allows for minimal disturbance to the surrounding area, preserving existing landscaping, topsoil, and natural features.

Electric and Hybrid Options

The availability of electric and hybrid mini excavators provides zero-emission options for material handling in environmentally sensitive areas or indoor applications.

Future Trends

Electric and Hybrid Models

The material handling industry is increasingly adopting electric and hybrid mini excavators. These models offer zero emissions, reduced noise levels, and lower operating costs, making them ideal for work in urban areas, indoor applications, and environmentally sensitive locations.

Advanced Technology Integration

GPS guidance systems, load monitoring technology, and automated control systems are being integrated into material handling equipment to improve efficiency and safety. These technologies can help operators optimize load distribution, track material movements, and prevent overloading.

Enhanced Attachments

Manufacturers continue to develop new attachments specifically designed for material handling, including more efficient grapples, specialized buckets for different materials, and tools with improved safety features.

Telematics and Remote Monitoring

Remote monitoring systems provide real-time data on machine performance, maintenance needs, and operational efficiency. This technology allows fleet managers to optimize equipment utilization and reduce downtime.

Autonomous Operation

The development of autonomous and semi-autonomous mini excavators is underway, with the potential to revolutionize material handling operations by allowing machines to perform repetitive tasks with minimal human intervention.

Conclusion

Mini excavators have transformed material handling and loading operations by providing the perfect combination of power, precision, and versatility for modern job sites. Their ability to work in confined spaces while delivering substantial lifting capacity makes them essential for construction, landscaping, agriculture, and industrial applications. With their low environmental impact, improved safety features, and ever-advancing technology, mini excavators will continue to be the preferred choice for contractors and operators looking to handle materials with efficiency, precision, and safety. As technology continues to advance, the role of the mini excavator in material handling operations will only become more important, offering new capabilities and efficiencies for the industries that rely on them.